What do professional mechanics do all day? What is the soundtrack to happy spannering? How do Condor's workshop guru's get the cassette so shiny? We spend a day in the Condor workshop.

Some riders love fettling and cleaning after a ride, but most of us want to head inside, raid the fridge, and relax. There is no escaping the fact that bicycles need TLC to perform at their best, and Gray's Inn Road has the gurus to relieve the chore of maintenance.

We spent the day following the workshop team as they refurbish, fix, and peel back the layers of grime in order to return bikes to peak performance.

The day begins at eight in the morning. You'd imagine that a workshop is repetitive, but not for Andrea and John. "Every day is different. Yesterday we received a vintage frame back from the painters. So I set about restoring and polishing a thirty-year-old Campagnolo groupset ready for the bike", explains head cechanic, Andrea Cattolico.

"Dirt and grit mixes in with grease to form a paste, which works its way into the smallest spaces."

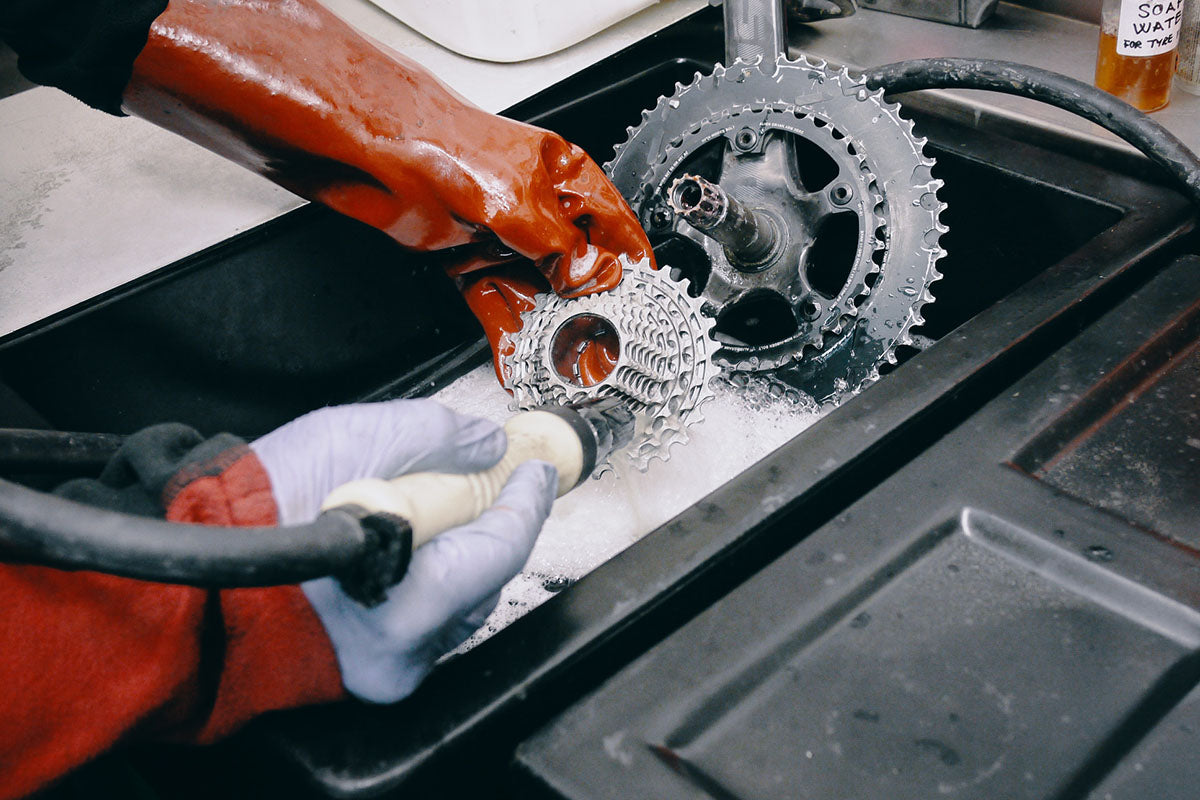

By mid-morning, John is part way through a general service — which, like a full service — involves removing all the running gear from the bike. "Grease is worn away over time. Dirt and grit mixes in with grease to form a paste, which works its way into the smallest spaces", John explains, as he dunks a SRAM Red chainset into an environmentally-friendly solution and starts to scrub.

Then he moves onto cleaning the cassette, chain, and rear derailleur before setting aside. Whilst the drivetrain dries, attention is turned to cleaning the bottom bracket and applying a fresh layer of grease "to keep out the water and the chainset spinning smoothly."

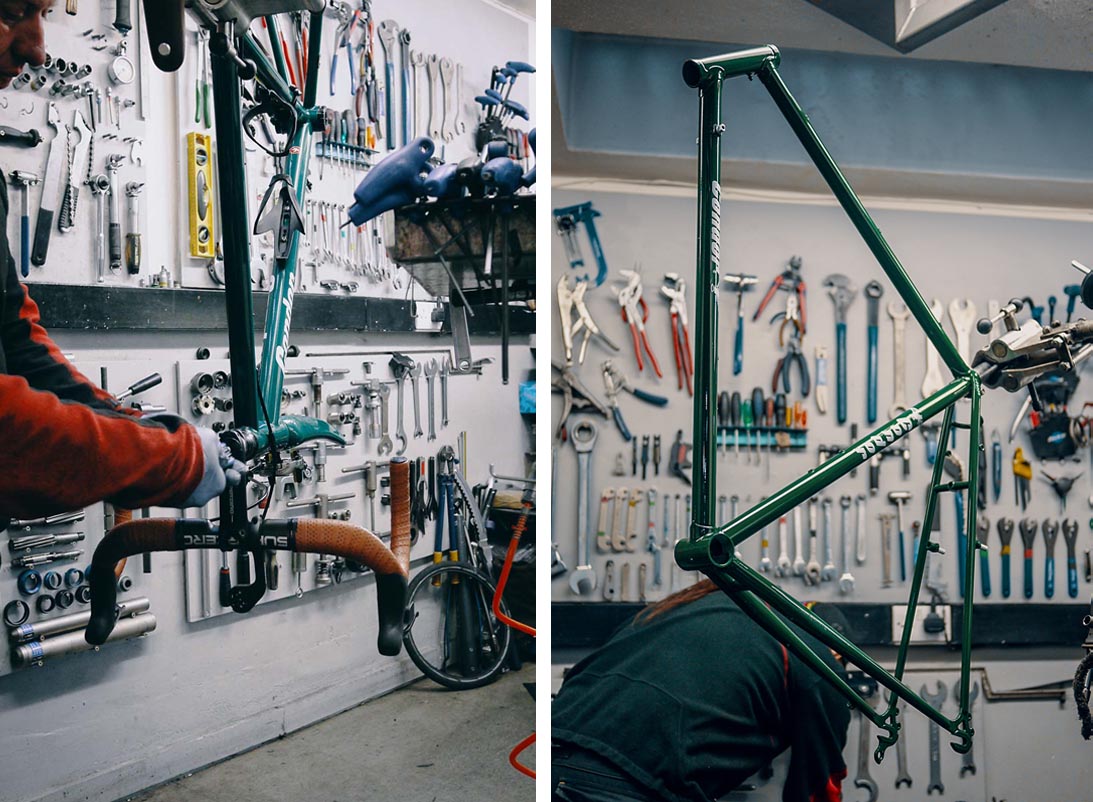

John then swings the Condor Super Acciaio completely vertical to service the headset. The handlebars hang down as he strips the headset, cleans the races, and replaces the bearings.

The duo are working to a soundtrack of easy eighties classics, and as Kate Bush ends, Andrea puts his new job in the stand, a refurbished 1988 Condor Italia. By pure coincidence, both stands are now occupied by steel green Condor frames, except there is a twenty-five year age gap between the models.

Andrea has a facing tool he's customised for older frames, and slots it into the bottom bracket to clean back excess paint on the Reynolds 531 frame and cut a thread.

The green Condor Super Acciaio is now ready to have the chainset refitted, derailleur, and an ultra-shiny cassette, before the gears and brakes are re-aligned. The last task for John is to check the wheels are true and inspect the hubs before heading off for lunch.

"The best maintenance tip I can give is fit mudguards in the winter."

Having seen nearly every kind of bike pass through his workshop, we asked Andrea for his one tip to keep a bike working well. "Prevention is better than cure. The best maintenance tip I can give is fit mudguard in the winter. They can slow the wear of parts by stopping dirty water spray all over your components", he replies. John adds: "It's simple to wipe your rims and inflate your tyres. Maybe leave a note on your fridge. Avoid punctures and you can get everywhere without as much effort."

Next on the job sheet is a fleet of eight Bromptons, which all require hinge replacements and full servicing. The bikes are used by a large city-based business for staff to move around the capital. Naturally, they have high annual mileage and, as a shared resource, may not always be treated with utmost care.

Condor is one of a small number of Brompton retailers with Premier certification, approving Condor mechanics, including John and Andrea, to carry out specialist work.

The day wraps up with a free of charge check-up for a rider who recently bought a Condor Bivio Gravel, and Andrea builds a wheel with a Gipiemme carbon rim.

"There isn't a month or season than is better or worse. In the winter bikes are a bit more dirty but in the summer, riders remember to bring out there bikes which they locked away for months ", explains Andrea. "We are lucky, we have a good reputation, especially as a Campagnolo maintenance centre, and we see amazing machines, unusual things, it is nice to work on a wide variety."